How to Select the Best Work Holding Devices for Precision Machining?

- Home

- /

- How to Select the Best Work Holding Devices for Precision Machining?

Proper workholding devices go a long way toward ensuring CNC workstations remain efficient and productive, delivering optimum results. They function at the heart of various machining operations and are critical for security and stability.

However, how do you choose workholding devices that work for your business? What are the various types of workholding devices in machining?

There are several ways to get a machining job done. Whether you are in the die and mould industry or an aerospace engineer, a machining business expert is aware of this fact.

However, the workholding devices and tools must be top-notch, reliable, and most importantly, ‘precise’. It is crucial to learn about the various types of workholding tools to find the ones that best suit your machining needs.

In this comprehensive read, let’s explore the common types of workholding devices and when to use them correctly.

We will also highlight the common mistakes in workholding selection, helping industries make smart choices.

Let’s begin.

What Are Work Holding Devices?

Workholding devices are apparatus parts used in machining that secure, stabilize, and hold workpieces in place during various processes or assemblies.

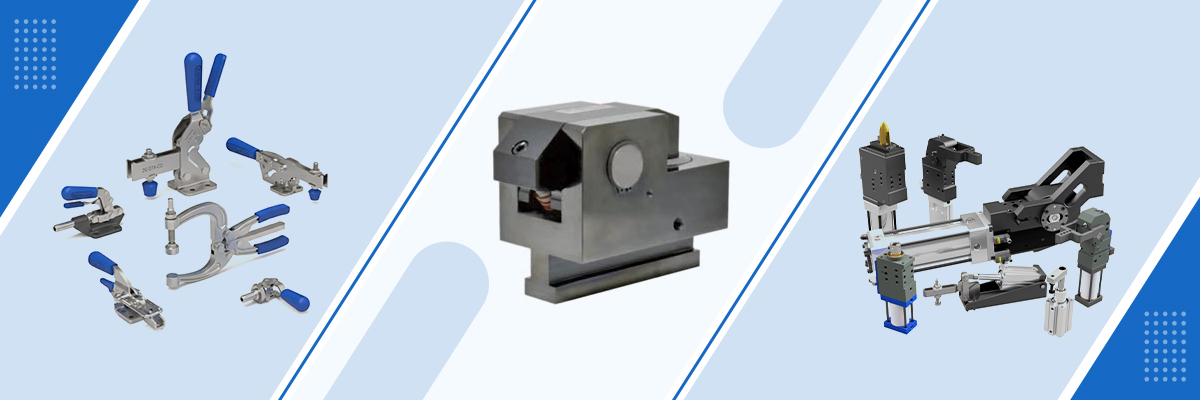

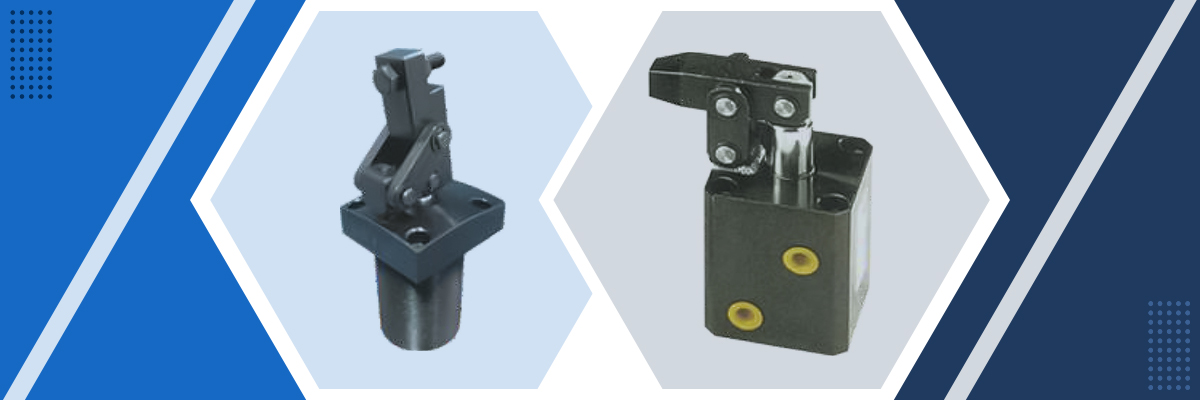

At its core, workholding devices range from clamps and vices to tool holders and fixtures – each uniquely designed to hold a specific apparatus.

Over the years, numerous workholding devices have been upgraded to accommodate further advancements in machining, leading to greater efficiency.

They are used across various machining activities – welding, assembly, and more. The robust support and secure positioning of each type of workholding tool offer precision and safety.

Key function of workholding devices –

- They help locate various machining parts and align the workpieces so the machine can operate correctly.

- They are utilised in the clamping mechanism, and the sufficient force they provide keeps the parts firmly in place.

- They are supporting devices and create stable contact points between various workpieces.

Workholding devices are crucial for CNC machining, where mass production, operator protection, and seamless operation are mandatory. They reduce overall setup time and process complexity.

Common Types of Work Holding Devices and When to Use Them

Now that we know what workholding devices are, let’s learn about the various types and how to use them correctly in various machining activities.

Remember, selecting the correct device is a balance between your part’s geometry, production volume, and the required level of precision.

Here are some of the standard workholding names in the machining world –

1. Machining Vices

The vice is an ancient and faithful piece in CNC machining and is widely used across multiple industries. It consists of two parallel jaws – one fixed and one movable – that use a screw mechanism to exert pressure on a workpiece.

When to use them: Vices are ideal for rectangular or square workpieces. They are the go-to for milling, drilling, and tapping operations on parts with flat, parallel surfaces.

Pro Tip: For high-precision work, use precision-ground vices with a pull-down mechanism that prevents the workpiece from lifting from the work station as the jaws tighten.

2. Chucks

Chucks are primarily used in lathe operations (turning) but are also found in indexing heads on mills. They typically feature three or four jaws that move in unison or independently.

- Three-Jaw Chucks: Best for hexagonal or round stock, and they provide automatic centring.

- Four-Jaw Chucks: Used for irregular shapes or when you need concentricity, as each jaw can be adjusted independently to dial in the part.

- Collet Chucks: Use a sleeve with slits or collets to provide 360-degree contact. These chucks are superior for small, high-speed parts where surface finish and runout are critical.

3. Clamps and Strap Clamps

When a part is too large or oddly shaped for a vice, strap clamps are used. These use T-slots on the machine table to bolt the workpiece directly to the table for a secure, lasting hold.

It is also vital to learn about the various types of clamps available in the market, including toggle clamps, pneumatic and magnetic clamps, pinch clamps, and more.

When to use them: Large plates, engine blocks, or castings that require machining on the top surface.

Caution: Improper clamping pressure can distort thin-walled parts. Always place supports directly under the clamping points to prevent bowing of lighter workpieces.

4. Fixtures and Jigs

While often used interchangeably, fixtures and jigs are different workholding devices. A clamping fixture holds the work in a fixed position, while a jig holds the work and guides the cutting tool. A jig is a common tool in manual drilling.

When to use them: High-volume production. Custom fixtures are engineered for a specific part, allowing for rapid loading and unloading (often called tombstones in horizontal machining centres).

5. Magnetic and Vacuum Work Holding

For parts that are extremely thin or cannot be marred by jaw marks, non-mechanical holding is used.

Magnetic Chucks: Ideal for ferrous metals (iron/steel) in grinding operations.

Vacuum Tables: Perfect for thin aluminium sheets or non-metallic materials like wood and plastic, where traditional clamping would crush or bend the material.

6. Indexing Heads and Rotary Tables

They are precision workholding devices that allow workpieces to rotate accurately during angular machining.

- Indexing Heads: Also called the dividing head, this specialised head accurately divides circular workpieces into equal parts for precise angles.

- Rotary Tables: It is a positioning device for rotating workpieces and works in conjunction with the indexing heads for smooth machining.

These are only a few of the standard workholding devices that offer versatile benefits across various CNC activities.

Factors to Consider When Selecting Work Holding Devices

When choosing a device for CNC workholding solutions, machining, drilling, or welding activities, tools cannot be just for fitting the workstation. It must perform, and perform well enough for accuracy and safety.

So, when choosing workholding devices, consider these five pillars –

Part Geometry and Size

The shape of your part must be the primary filter when picking workholding devices. A round shaft requires a chuck or V-block; a flat plate requires a vice or vacuum table.

Consider whether the workholding device obstructs the tool’s path. If you need to machine all five sides of a cube in a single setup, a standard vice might not work, and you may need a 5-axis self-centring vice.

There are several other factors to consider when it comes to the shape and size of workholding devices.

Material Hardness and Fragility

If you are machining aerospace-grade titanium, you need a massive clamping force to withstand the cutting pressures. However, if you are machining a thin-walled plastic housing, those same forces will cause it to crack.

Use soft jaws, made of aluminium or plastic that can be machined to match the contour of your part and distribute pressure evenly.

Production Volume

For Low Volume (Prototyping): Use versatile, modular tools like standard vices and strap clamps.

For High Volume (Mass Production): Invest in dedicated hydraulic or pneumatic fixtures. The goal here is to minimise setup time – the time the machine is sitting idle while you swap parts.

Cutting Forces

The direction of the cutting force matters. During heavy face milling, lateral forces are immense. Your workholding device must not only hold the part down but also prevent it from sliding across the workstation.

Accuracy and Repeatability

Repeatability is the ability to remove one part, replace it with a new one, and have the new part sit at the exact spatial coordinates (x-axis or y-axis). If your workholding setup lacks repeatability, you will waste hours touching off tools for every single part.

Common Mistakes in Work Holding Selection

Even seasoned machinists fall into these traps, and there is nothing to be ashamed of it. Avoiding them can save thousands in scrapped parts and broken tools.

1. Over-Clamping

Excessive force can cause internal stresses. When the machined part is released from the vice, it springs back or bounces, warping your perfectly flat surface.

2. Ignoring Vibration

If a part is not properly supported, it will vibrate in place and introduce inaccuracies. This leads to poor surface finishes and can cause carbide cutting tools to shatter. Always support the overhang of a workpiece.

3. Neglecting Tool Clearance

It is demotivating as a CNC expert to hear a spindle crash into a hardened steel vice jaw. Always simulate your toolpaths to ensure the tool holder clears the clamping hardware.

4. Poor Maintenance

Chips and coolant can get inside chucks and vices, affecting their grip strength. Regular cleaning and lubrication are vital for maintaining clamping repeatability.

These are only a few such common mistakes that occur when handling workholding devices. It is vital to be aware of and avoid such instances to protect tools better and extend their longevity.

Jaypee Associates for All Work Holding Device Needs

In precision machining, the cutting tool is only as good as the workholding that supports it. Whether you are using a simple bench vice or a complex hydraulic tombstone, the goal remains the same: stability.

It is vital to understand each device’s strengths and weaknesses and match them to your specific material and volume needs. At Jaypee Associates, we ensure that your shop remains a place of precision rather than a place of re-work. We have an extensive collection of workholding devices, tooling, and toolholders designed for a wide range of machining activities across industries.

From clamps to levelling jacks and Swiss-cut drills to endmills, we offer tools that fit a range of machining needs. Each workholding piece of equipment is sourced from quality brands and delivers on its promise.

Explore the collection and invest in quality work holding today!