Manual vs Hydraulic vs Pneumatic Clamping Systems: Which One Fits Your Setup?

- Home

- /

- Manual vs Hydraulic vs Pneumatic Clamping Systems: Which One Fits Your Setup?

If your business deals with industrial and mechanical processes, you are probably aware of clamping systems. They are one of the integral parts of various machining activities that hold workholding parts in place.

However, clamping systems come in varied types and mechanisms – manual, hydraulic, pneumatic and more. Each is unique, works differently and has its pros and cons.

Which type of industrial clamping system is ideal for your setup? What are the various types of CNC workholding clamps that deliver ideal outcomes?

In this comprehensive piece, let’s explore the various types of clamping systems, with a focus on the hydraulic, pneumatic, and manual systems. We will cover the basics, how each compares to the others, and how the clamping system will work in your setup for precision and efficiency.

What Is a Clamping System?

In the CNC machining industry, manufacturing devices often have several small workpieces that require secure holding for optimal functionality. A clamping system secures the workpieces and tools in a fixed position for various operations – cutting, welding, moulding and more.

For repeated tasks in a workstation, a clamping system offers accuracy and stability without causing wear and tear of parts.

These systems are available in various types and kinds to meet varied machining requirements across businesses – manufacturing, die and mould, and construction, to railways.

Why Clamping Systems are Essential in CNC Workholding?

Whether manual, hydraulic, or pneumatic, clamping systems have their own set of benefits. They are indeed a functional component across industries and machining activities.

Let’s take a look at the advantages –

Precision and Accuracy

- CNC machining involves high-speed cutting tools that generate significant forces.

- Clamping systems prevent workpiece movement or vibration, ensuring dimensional accuracy and tight tolerances.

Safety

- A loose workpiece can cause tool breakage or accidents.

- Proper clamping protects operators and equipment by keeping the workpiece firmly secured.

Efficiency and Productivity

- Stable workholding reduces the need for rework and scrap.

- Automated clamping systems minimise setup time and allow faster changeovers, boosting throughput in modern factories.

Consistency and Repeatability

- CNC machining often requires producing identical parts in large batches.

- Clamping systems provide repeatable positioning, ensuring uniformity across all parts.

Adaptability to Materials and Operations

- Different materials (metal, plastic, composites) require different clamping forces.

- Specialised clamps (hydraulic, pneumatic, and magnetic) adapt to diverse machining needs, improving versatility.

Why Investing in Good Clamping Systems Matters?

Not using well-manufactured clamping systems leads to various risks during machining operations –

- Workpiece shift leads to inaccurate dimensions and poor surface finish.

- Tool damage means costly downtime and repairs.

- Operator hazards again mean flying parts or broken tools.

- Reduced efficiency often means longer cycle times and higher scrap rates.

Clamping systems are not just accessories. They are fundamental to CNC-machined components, guaranteeing precision, safety, and productivity, and enabling modern automation and smart manufacturing.

Understanding the Basics of Manual, Pneumatic, and Hydraulic Clamping Systems

While there are several types of clamping systems, today let’s focus on the three primary ones –

- Manual

- Pneumatic

- Hydraulic

Each is unique and suited to a variety of machining applications. They are a helpful addition for workpiece security during machining and other operations.

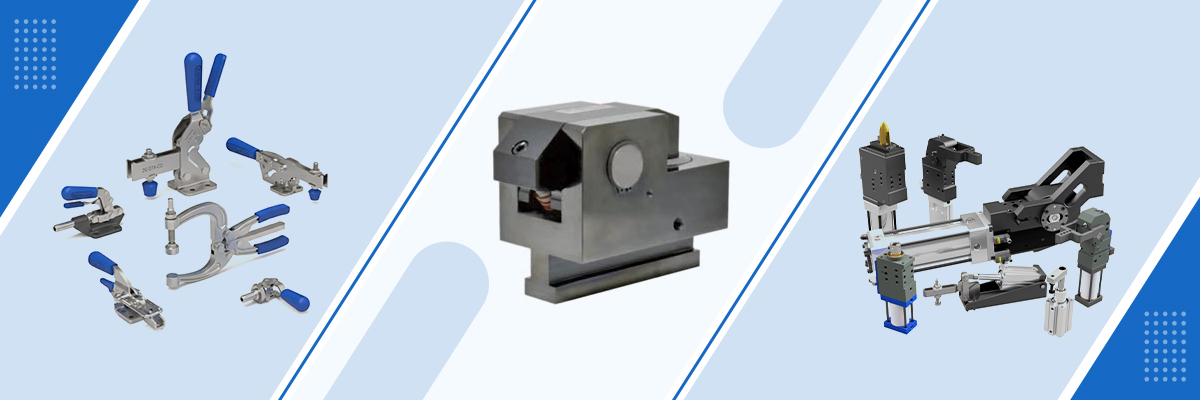

Manual Clamping System

Manual clamping systems are simple, cost-effective, and versatile workholding solutions. However, as the name suggests, they rely on human-operated mechanisms, such as vices, bolts, or wedges, to secure a workpiece during machining.

Manual systems are widely used for small-batch production, prototyping, and situations where flexibility and low setup costs are more important than automation.

Unlike hydraulic or pneumatic systems, manual clamping does not require external power sources. They depend on mechanical force applied by hand.

Manual clamping systems are –

- Simple, low-maintenance, and cost-effective

- Resistant to dirt and shop-floor conditions and reliable even in harsh environments

- Varied in options: single-acting vices, centric clamping vices, multi-vices, and 5-axis vices

- Customisable, and the jaws and fixtures are adaptable to different part geometries

- Easy to adjust for different workpiece sizes and shapes.

Cons –

- Manual systems have slower setup times compared to automated clamping.

- It is entirely operator-dependent and may lead to inconsistent clamping force.

- Not ideal for high-volume production where speed and repeatability are critical.

- It is less ergonomic for frequent setups where speed is essential.

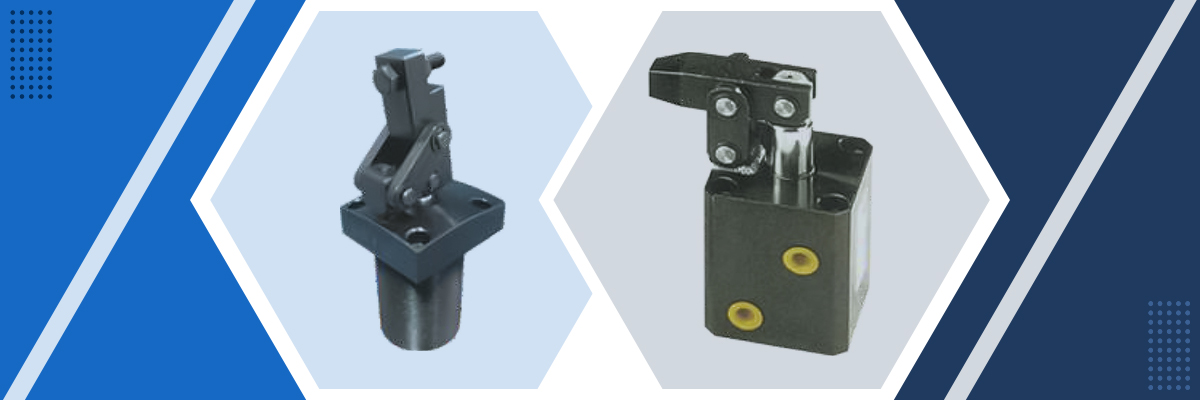

Pneumatic Clamping System

A pneumatic clamping system uses compressed air to secure and hold CNC workpieces. They offer the ideal speed, consistency, and automation advantages during high-volume productions.

A pneumatic clamp has air-actuated cylinders to generate clamping force. The cylinder moves a piston that applies pressure to the clamp, securing the workpiece. Releasing the air pressure disengages the clamp, allowing fast part changes.

The core features include –

- Air-powered actuation that eliminates manual tightening.

- Fast cycle times, which are ideal for repetitive operations.

- Consistent clamping force that reduces variability compared to manual systems.

- Compact and versatile designs, including toggle clamps, swing clamps, and self-centring vices.

- Automated integration that can be controlled via machine signals or robotic systems.

- Uniform clamping pressure and repeatability that deliver consistent machining quality.

- Zero to minimal manual intervention leading to fewer workholding risks and injury.

Cons –

- Pneumatic clamps require a compressed air supply, which adds to the infrastructure cost.

- It has a lower clamping force compared to hydraulic ones, and is not ideal for heavy-duty setups.

- It has a higher upfront cost and is a hassle for small-scale workshops.

Hydraulic Clamping System

A hydraulic clamping system uses pressurised fluid to generate strong, consistent clamping forces during machining. It is ideal for heavy-duty machining and high-precision applications, and is among the most powerful and reliable workholding methods.

The setup has hydraulic cylinders and fluid pressure to secure the workpiece. When hydraulic fluid is pumped into the cylinder, it moves a piston that applies force to the clamp.

Its unique benefits are –

- Strongest clamping force compared to pneumatic or manual systems.

- Consistent pressure, irrespective of operational variations.

- The durable finish caters to industrial setups that demand advancements.

- It is an automation-ready setup and works effortlessly with CNC machine controls.

- Hydraulic clamping systems are available in varieties – swing clamps, pulls and vices.

- The setup has superior holding power and manages large, heavy, or complex workpieces.

Cons –

- Hydraulic clamping systems require pumps, hoses and hydraulic units – overall an expensive setup.

- The fluid may leak and cause contamination, which affects performance.

- It is an infrastructure-rich setup compared to its manual and pneumatic counterparts.

Which Clamping System Fits Your Setup?

When choosing the right clamping system for CNC workholding, it depends entirely on your production scale, material type, precision requirements, and budget.

Let’s break it down so you can see which one fits your setup best –

Manual Clamping System –

It’s low-cost, simple to use, and offers flexible use across workstations. The drawbacks are a slower setup, operator-dependent consistency, and a lack of ideality for mass production.

Best for: Small workshops, prototyping, low-volume production – if you’re doing custom jobs, one-offs, or experimental machining.

Pneumatic Clamping System –

It provides fast clamping and unclamping, maintains consistent pressure, and can be integrated with automation. The downsides include the need for a continuous compressed-air supply and a lower force than hydraulics provide.

Best for: Medium-duty machining, high-volume production where speed matters – if you need quick changeovers and repeatability in a production line.

Hydraulic Clamping System –

It offers a very high clamping force, precision, repeatability, and vibration-free machining. The disadvantages include higher costs, the need for hydraulic infrastructure, and increased maintenance.

Best for: Heavy-duty machining, large or complex workpieces, industries like aerospace or automotive – if you’re machining large batches of heavy parts with tight tolerances.

So, in conclusion –

- If you have a small shop or are just prototyping, go Manual.

- If you are in medium-scale production with speed needs, choose Pneumatic.

- If you are in heavy industry, handling large parts and tight tolerances – invest in Hydraulic clamping systems.

Finding the Ideal Clamping Tools at Jaypee Associates

While it is ideal to find the most suitable clamping setup for your workstation, it is also essential to find high-quality workholding, tools, and toolholders.

Whether you are looking for a hydraulic or pneumatic clamp, Jaypee Associates is the authorised distributor you need.

With over two decades of experience, we have an extensive collection of workholding essentials – from clamps to jacks, and screws to levers – that meet quality standards and cater to various industries.

Your search for the most ethically sourced, high-quality workholding devices ends here!