Toggle Clamp Types and Their Uses – The Complete Guide

- Home

- /

- Toggle Clamp Types and Their Uses – The Complete Guide

Are you struggling to keep your machine component from slipping during cutting or drilling? Do they keep vibrating in the wrong hours? Doing this manually can be laborious and dangerous. Furthermore, working with an unstable machining system can result in poor cuts and damaged machine components.

Toggle clamps provide quick, practical solutions to these problems. Within seconds, these simple mechanical devices achieve a secure grip on your materials. No more holding the pieces by hand or using unsafe workarounds. And no more do-overs when a slight movement disrupts work.

But here’s the tricky part: choosing the wrong toggle clamp type brings along a whole new set of headaches. You might buy a clamp that’s the wrong size. Or select one that does not have enough clamping force. A lack of knowledge will certainly run your pockets dry by leading you to buy tools that don’t meet your individual needs.

This comprehensive guide clears many of the doubts surrounding the various types of toggle clamps. You will discover exactly which clamp works best for your application.

What Is a Toggle Clamp?

A toggle clamp is a safe device for holding things fast. It uses a lever-driven mechanism to generate a strong holding force on machine components—the clamp locks in place via an over-centre mechanism. Thus, you don’t need to press the clamp against the surface to keep it in place.

Generally speaking, a toggle clamp consists of a handle, the clamping arm or plunger, a base to mount it to a surface, and a linkage mechanism. Once the handle locked position is reached, the linkage pivots slightly over centre.

This over-centre pivot of the linkage causes the clamp to self-lock in position. It maintains holding force even under excessive load.

Toggle clamps function via a system of pivots and levers. The handle is the most direct interface for exerting force to operate the clamp. The linkage system transfers this movement in time to create a decisive clamping action.

The clamping arm or plunger is what the toggle clamp exerts holding force on when you clamp. Most designs have a clamping spindle that seats into the machine component, with a protective pad to prevent damage to the clamped surfaces.

How to Use Toggle Clamps?

Understanding how to use it properly will help you stay safe and extend its life. The first thing you want to do is mount the clamp securely to a clean, flat surface. Pick a mounting surface that is strong enough to resist the clamping forces. Use some chosen bolts or screws through the mounting holes in the base.

Position the clamp so the spindle contacts the strongest part of your machine component. Please do not move it too high or too low. Set the spindle height accurately. Now, when you engage the handle, the linkage should move a little past centre and lock over centre, but not excessively.

Pull the handle in a controlled manner to get a confirmation click when you are locked in a clamping position under pressure. Do not add any extensions to the handle lever. Also, refrain from hitting the lever with a hammer to apply force.

Keep your hands and fingers out of the way of the linkage while in use. The pivot points can pinch. Also, verify that your machine components are securely locked before machining, welding, or other operations.

After you have the spindle position marked for consistent application, you can use a lock nut to maintain the setup. If you are using multiple toggle clamps on one fixture, be sure to apply the same excessive clamping force in the same fashion as your pressure application to spread the pressure evenly.

Application of the Toggle Clamp

A toggle clamping system can multitask in manufacturing. The somewhat simple, almost “dumb” purpose of a toggle clamp makes it an essential yet valuable item in medium to smaller shops. When it comes to the heavier (larger) workspace, they can help you manufacture more and more of the same part or product.

1. Woodworking

Woodworkers use toggle clamps to build jigs and fixtures. They hold wood pieces during routing, cutting, and drilling. You can also use them to keep material on crosscut sledges, tapering jigs, and tenoning fixtures, for example.

As you know, using a toggle clamp requires a simple “instant-release” function. It can speed up repetitive tasks while still holding the material true and accurate as you cut, trim, shape, drill, etc.

2. Welding, Fabricating, Assembly

Heavy-duty toggle clamps are great for a welded environment, as they hold the metal piece while tacking and welding. They are heavy, sturdy, and rugged enough to withstand the intense heat and pressure that often accompany them.

If you use an Industrial toggle clamp design and a holding speed, you can expect them to work even with sparks and hot splatter hitting them.

3. CNC Machining Operations

You can use low-profile toggle clamps on CNC machines. Low-profile toggle clamps can hold down stock material as work pieces on a rip saw/part machine bed without blocking any tool paths. Again, you can quickly alter them, reducing setup time between parts. It will allow you to make more of the same parts faster, increasing productivity in a machine shop.

4. Plastic and Injection Moulding

Toggle clamps secure two mould halves during injection moulding. They hold parts for secondary processes such as trimming and drilling. In addition, you can use them in assembly fixtures to clamp plastic components for bonding processes.

5. Electronics Assembly

In electronics manufacturing, smaller precision toggle clamps serve the industry well. They hold printed circuit boards (PCBs) during soldering, inspection, and testing. The toggle clamp is very important for providing a controlled clamping force. It prevents delicate components from being damaged.

6. Automotive Manufacturing

Automotive manufacturers are another industry that often uses toggle clamps. They hold body panels in place. At the same time, they are welded together on the assembly line. Interior components are also often fixtured with toggle clamps during assembly-line installation.

Once you clamp the parts, they do not move- that’s the beauty of the toggle clamping system. It provides consistent, repeatable positioning of parts —often thousands of them.

7. Packaging & Food Processing

Various types of automated packaging equipment utilise toggle clamps. There’s also potential for using the toggle clamps to hold containers in place while you fill, seal, and label the goods. There are stainless steel toggle clamps designed for hygienic food processing and non-corrosive operations.

8. Quality Control Fixtures

Toggle clamps help position parts in inspection or quality control fixtures. They hold the positioning parts in a consistent location for comparison against gauges or coordinate measuring machines (CMMs). Returnable positioning is a benefit of toggle clamps in the quality control processes.

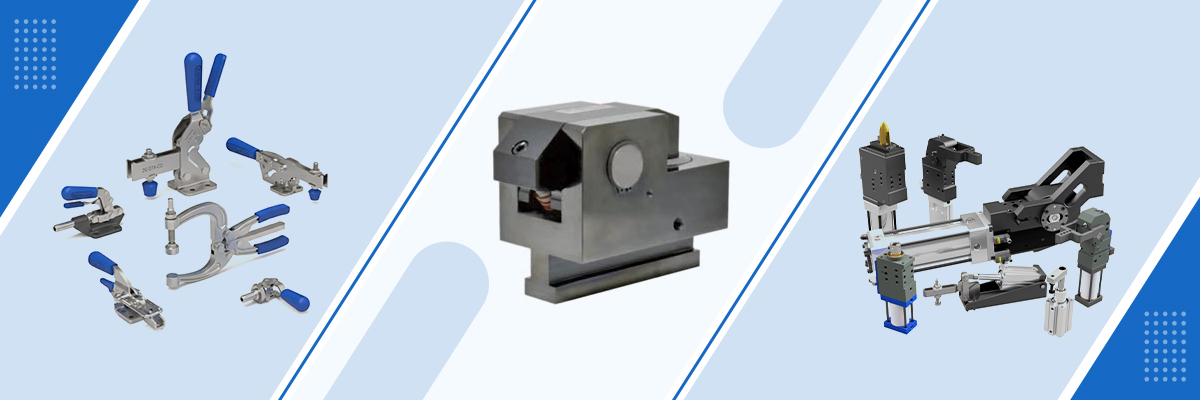

Toggle Clamp Types

The different styles serve their own operational needs and work area constraints. Each style offers its own strengths and weaknesses for specific applications.

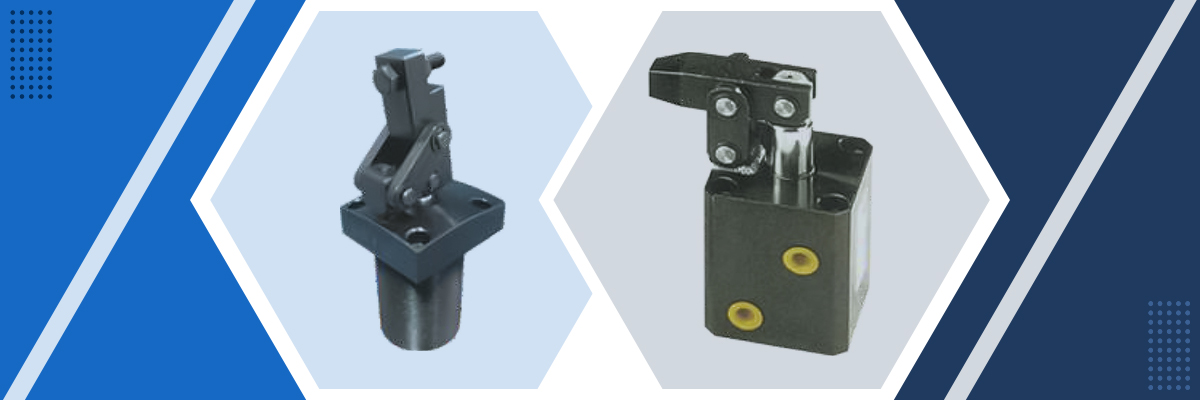

1. Vertical Toggle Clamp

The vertical toggle clamp’s handle is upright when the clamp is open. The handle and arm are opposite each other: the arm travels in and out of the work area, while the handle moves up/down. Push the handle down while holding the clamp open to engage the clamp.

This design allows a full range of motion and the best access, as both the handle and arm rise out of the work area. This is a unique feature of the vertical style. It eliminates operator fatigue when performing repeated clamping actions.

Vertical toggle clamps are a standard part of a wide range of general woodworking and assembly applications. You can use them on conventional workbenches and work jigs if there is ample height to accommodate the clamp’s position. The holding capacity can range from light duty to well over 750 pounds, depending on the clamp design.

2. Horizontal Toggle Clamp

A horizontal toggle clamp’s handle remains parallel to the mounting base when in the clamp position. The horizontal clamp’s style can be instrumental in tight spaces where vertical clearance isn’t easy.

The handle lies flat during the clamping operation. This allows the operator or assembler to work above the clamp’s motion. The clamping action can generally remain the same relative to the vertical style without action. Still, the hand and the linkage are typically redesigned for horizontal action.

These clamps are standard on welding fixtures and within assembly jigs. They offer holding capacities of up to 771 lbs for industrial applications. Their small size frees up workspace on cramped fixtures, allowing for maximum usable workspace.

3. Push-Pull Toggle Clamp

Push-pull clamps operate via a sliding plunger rather than a pivoting arm. Instead of moving in an arc, the handle will move forward or backward along the clamp’s axis. The motion produces straight-line clamping action.

These clamps are ideally suited for recessed applications. The straight-line motion allows clamping in confined spaces that rotating arms might not fit. The plunger also allows for easy positioning against a vertical stop.

Push-pull type clamps are ideal for electronic assembly and other precision positioning applications. They are found in practically all CNC workholding applications and in mould holding applications. Clamping force is around 385 lbs or less maximum in this type of clamp.

4. Latch-Type Toggle Clamp

Latch-type clamps connect two parts by pulling them together. They consist of a clamp body and a separate latch plate or U-hook. Hook the latch to the latch plate that fits on the machine fixture, and then pull down the handle to complete the connection.

This type of clamp works great for closing and sealing applications. A few examples where this type of clamp is effective include moulding halves, chamber doors, access doors, and equipment lids. The handle’s pulling action creates a strong compressive force between the two mating surfaces.

Heavy-duty toggle clamps in a stuff-off configuration can hold up to 1,984 pounds. Therefore, they are suitable for harsh closure applications. The hook-and-latch design allows for quick connection and disconnection.

5. Squeeze-Action Toggle Clamp

Squeeze action clamps are similar to locking pliers in style. They are portable hand tools because they do not need to be fixed to a location. You squeeze the two handles together to clamp the jaws onto the machine component. The toggle mechanism locks the jaws in place until disengaged by the release lever. The plier-style design makes them easy to transport.

These clamps are ideal for temporary fixturing and field work. Sheet-metal workers use them quite often. They are helpful when you need to clamp a machine component at several different locations. They will hold up to 705 pounds, depending on the model.

6. Cam Action Toggle Clamp

Cam action clamps can accommodate differences in machine component thickness. They use a spiral-shaped cam, or rising cam, rather than a fixed linkage. The cam allows for a more gradual clamping force as you use the handle.

With this design, you do not have to make frequent spindle adjustments. The cam will automatically adapt to dimensional differences. All of this equates to improved production time when dealing with rough castings, forgings, or wood with varying thicknesses.

Manufacturing contexts with multiple dimensions in parts benefit most from toggle clamps. The self-compensating action of toggles minimises setup time. The operator can go from clamping a part to a given thickness to clamping a combing to an entirely different thickness without having to make a manual adjustment.

7. Pneumatic Toggle Clamp

Pneumatic toggle clamps replace the manual handle with an air cylinder. The same linkage systems serve as manual clamps. The only difference is that they are actuated by compressed air. The air supply is responsible for the clamping and the releasing cycles.

These industrial toggle clamp designs convert manual toggle clamps to automatic toggle clamps for applications that utilise automated production lines. These automatic toggle clamps can clamp quickly and repeatedly without requiring operator intervention. Pneumatic clamp designs can easily synchronise with robotic cells or automated assembly systems.

High-volume manufacturing is based on pneumatic clamps. There is nothing more consistent than a pneumatic clamp delivering the same force thousands upon thousands of times. Control systems can coordinate multiple pneumatic clamps simultaneously in a fixture, with assembly components that operate in a complex manner across multiple pneumatic clamps.

8. Self-Adjusting Toggle Clamp

Self-adjusting clamps automatically accommodate the sizes of machine components. The linkage includes mechanisms to comply with machine component sizes. In self-adjusting clamps, adjustments are made by mechanically altering the linkage geometry while increasing the load on the machine component. It results in maintaining nearly constant clamping force across a range of heights.

A manual spindle reset is no longer a concern with self-adjusting clamps that automatically compensate for an increased machine component height. The productivity improvements are dramatic.

Custom production shops and adaptable assembly lines reap the most significant benefits. High-mix production environments allow for shorter changeover times. The automatic adjustment maintains quality while increasing throughput.

Understanding Key Components of a Toggle Clamping System

Understanding the function of all components of the toggle clamping system will assist in selecting and maintaining the performance of the clamps. Each element has a specific role in the clamp.

1. Handle or Actuator

The handle is the interface for the operator. It is a lever that engages and disengages the clamp. Most of the handles have soft grips that are comfortable to use and provide a safety factor.

2. Clamping Arm and Pressure Bar

This is the part of the clamp that will contact the machine component and apply pressure. Both vertical and horizontal clamps will use a pivoting bar. Push-pull clamps will apply pressure on a mechanism that uses a plunger.

3. Mounting Base

The mounting base is the means to attach the clamp to your fixture or workbench. It has holes to attach either bolts or screws. The base design will determine the clamp’s mounting style.

4. Linkage System

All parts of the device link together in the clamp, and the linkage is the most essential part. There are interconnected levers and/or pins that convert the handle input into clamping pressure. This gives the clamp a self-locking feature through over-centre geometry.

5. Adjustable Spindle

The spindle is threaded and provides height adjustment for various machine component specifications. The spindle will typically have a protective pad to prevent damage to the machine component surface.

6. Other Features

Many clamps can utilise optional accessories. Pneumatic models can come equipped with proximity sensors to confirm position. The cushion pack can be designed for delicate surfaces, or an extended arm can be added.

Industry Applications for Toggle Clamp Type

Based on the specific requirements, each industry has its own clamp setup. The application drives the product’s design.

1. Manufacturing, Assembly

Production and even basic assembly lines extensively utilise toggle clamping systems. The quick-release function speeds up repetitive tasks on such lines while providing consistent, repeatable positioning, thereby guaranteeing quality manufacturing.

2. Custom Fabrication

Custom fabrication facilities and job shops will use certain types of toggle clamps that can be used for multiple products. For example, a self-adjusting toggle clamp reduces setup time between different parts while also enabling versatility. This function is especially valuable in low-volume, rapid-changeover applications.

3. Aerospace Applications

Precision toggle clamps are used in the aerospace industry to secure fragile composite and aluminium parts for drilling and assembly. They provide solid positioning and controlled clamping force to prevent material distortion.

4. Medical Device Manufacturing

Toggle clamps made of stainless steel follow hygienic standards. Stainless steel toggle clamps are easy to clean. Any manufacturing or assembly rationale for medical devices will require the use of a toggle clamp. They will perform the repetitive positioning functions to ensure a consistent setup.

Jaypee Associates – Your Trusted Partner in Precision Workholding Solutions

Toggle clamps are a much-needed accessory for any manufacturing or fabrication business. Selecting toggle clamp types that will provide safety, efficiency, and precision to your work is the first step. Whether you need vertical toggle clamps for woodworking or heavy-duty toggle clamps for industrial applications, selecting the correct device is critical.

Recognising how toggle clamps fit into the broader workholding, tooling, and toolholder solution landscape strengthens your overall clamping strategy. Suppose you are looking for additional clamp options for your workshop. You can check out our comprehensive resource on the different types of clamps and how they are used in industry. It will help you learn how C-clamps, milling clamps, strap clamps, and more will work with your toggle clamp setup.

Head on over to Jaypee Associates to explore our complete range of workholding and tooling solutions for CNC applications. Our team of professionals will help you choose an ideal toggle clamp for your application.