Various Types of Clamps and Their Industrial Applications

- Home

- /

- Various Types of Clamps and Their Industrial Applications

What is a clamp? Are clamps needed in all machines? Which types of clamps are best for welding?

If these are queries you have in mind as an industrial professional, this is the perfect read for you.

Clamps are versatile tools used to hold, secure, and fasten machine components safely. They firmly hold two machine components together, preventing them from moving or vibrating.

Quality clamps are a boon to various CNC machining industries – from aerospace to automotive and construction to electronics. While holding the workpieces together, clamps ensure an effortless process, safer workstations and better manufacturing practices.

There are various types of clamps available in the market – each uniquely designed to meet varied machinery needs. For instance, F-clamps permanently hold attachments in place. Similarly, milling clamps securely hold the workpieces on the milling table to prevent unwanted movement during cutting and more.

These are only two of the many types of industrial clamps available. In this comprehensive read, we will explore various types, clamp uses, and accessibility across industries.

Let’s begin!

What is a Clamp?

A clamp is a mechanical device used to hold, secure, or fasten machine components firmly in place during various industrial and machining processes.

These devices prevent unwanted movement, vibration, or component displacement. They allow operators and machines to perform their work with stability and precision, be it welding, drilling, or assembling.

Clamps come in different shapes, sizes, and designs depending on the type of operation and the materials involved.

They can be manually operated using screws or levers, or powered by hydraulic or pneumatic systems for automation.

Regardless of their mechanism, the primary purpose remains the same: to provide a strong, secure grip that enhances accuracy and safety.

In industries like automotive, aerospace, fabrication, and construction, clamps are indispensable. In CNC machining, this tool holds components in precise alignment to achieve precise cuts, while in welding, it keeps metal sheets tightly together to ensure flawless joints.

A good-quality clamp ensures stability, improves operational efficiency, reduces setup time and prevents costly errors.

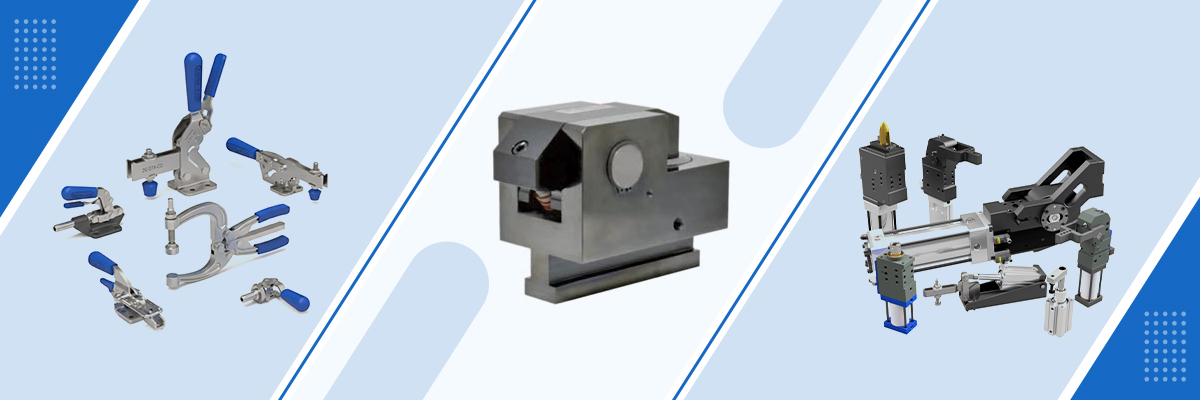

Different Types of Clamps

Clamps come in a wide range of designs and configurations. Each type is designed for specific applications and work environments.

Whether for holding heavy metal components during machining or securing delicate materials during inspection, there’s a clamp designed for every purpose.

Here are some of the different clamp types used across industrial sectors –

- C-Clamps

One of the most traditional and widely used types, C-clamps feature a C-shaped frame and a threaded screw mechanism. They are ideal for holding metal, wood, or plastic workpieces securely during machining, welding, or assembly.

The adjustable design makes them versatile for both light and heavy-duty tasks.

- F-Clamps

Also known as bar clamps, these feature a sliding arm that provides a greater adjustment range. F-clamps are used when a larger clamping area or greater flexibility is required.

They are commonly seen in metal fabrication, woodworking, and assembly lines where multiple workpieces need to be held together.

- Milling Clamps

Specifically designed for CNC milling machines, milling clamps hold workpieces firmly on the machine table during cutting or drilling.

They are engineered to resist high cutting forces, ensuring accuracy and vibration-free operation. Milling clamps are often paired with step blocks or support elements to create stable and adjustable setups.

- Strap Clamps

Strap clamps are one of the most common workholding tools used in CNC machining and fabrication. They consist of a flat metal strap secured at one end with a bolt or nut.

These clamps are ideal for holding large or irregularly shaped parts and are used in conjunction with step blocks or T-slot bolts for adjustable setups.

- Toggle Clamps

Toggle clamps provide quick-action clamping and release. They are the perfect tools for repetitive machining or assembly tasks.

Toggle clamps use a lever-and-pivot mechanism to apply a strong holding force with minimal effort. They are often found in production lines, inspection fixtures, and jigs.

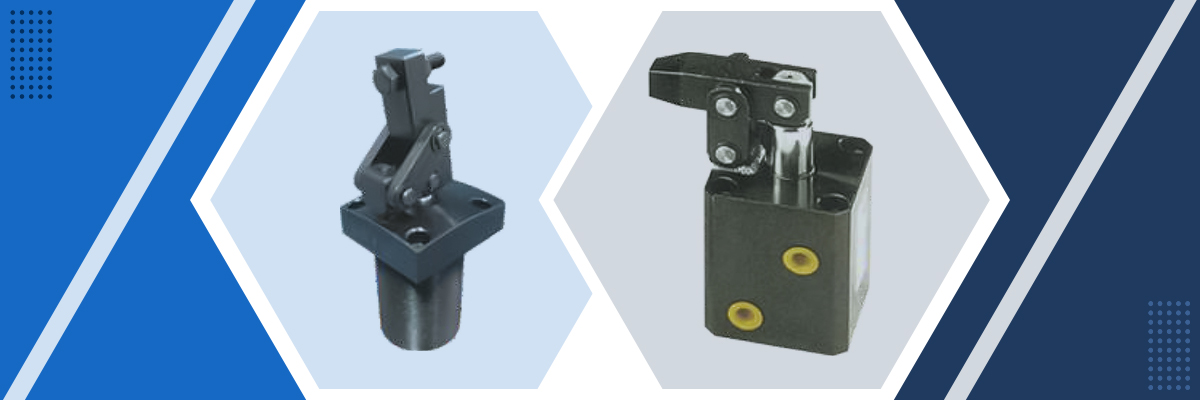

- Die & Mould Clamps

As the name suggests, these clamps are designed to securely hold dies and moulds during operations such as casting or injection moulding.

They can withstand high loads and temperatures while keeping the mould perfectly aligned.

- Side Clamps

Side clamps apply horizontal force rather than vertical pressure, keeping the workpiece’s top surface free for machining. This makes them ideal for CNC milling operations that require maximum tool access and clearance.

Each clamp type plays a role in improving machining precision, safety, and productivity. Selecting the right clamp depends on factors such as the workpiece material, the machining operation, the required holding strength, and the available workspace.

Together, these various clamps make modern manufacturing more efficient, accurate, and dependable.

Uses of Clamps in Various Industries

From CNC machining to construction, clamps play a crucial role in achieving high-quality output and operational efficiency.

Let’s take a closer look at how clamps are used across various industries –

- Automotive Industry

In the automotive sector, precision and safety are critical. Clamps are used to hold engine parts, transmission housings, chassis components, and metal sheets in place during machining, welding, and assembly.

Milling clamps, toggle clamps, and die & mould clamps are commonly used to ensure accurate alignment and vibration-free machining.

- Aerospace Industry

The aerospace industry demands extremely high levels of accuracy due to the complexity of components and tight tolerances involved.

Clamps, such as wedge clamps, side clamps, and precision vices, are used to hold lightweight yet intricate materials, such as aluminium or composite parts. These tools prevent movement during machining or inspection, ensuring flawless finishes and dimensional accuracy.

- Die & Mould Manufacturing

In die and mould manufacturing, stability and precision are vital. Heavy-duty die clamps and mould clamps securely hold dies during machining, casting, or moulding processes.

These tools and toolholders prevent misalignment or shifting, ensuring that every mould is produced with perfect detail.

- Fabrication & Welding

Clamps are indispensable in metal fabrication and welding shops. They hold metal plates, pipes, or assemblies in the correct position, ensuring precise joints and preventing heat-induced warping.

F-clamps, pinch clamps, and adjustable clamps are especially useful for maintaining alignment during tack welding or final welding.

- Construction Industry

In construction, clamps are used for scaffolding, formwork, and structural assembly.

Heavy-duty clamps secure beams, pipes, and panels, ensuring stability during construction or repair work. They also aid in temporary fastening during installations, allowing workers to handle large materials safely and efficiently.

- Medical Equipment Manufacturing

Clamps are equally vital in the production of medical devices and equipment, where high precision is mandatory.

Compact and precision clamps hold miniature components during machining or inspection. Their use ensures repeatable accuracy and maintains sterile, vibration-free operations in cleanroom environments.

- General Engineering & Workshops

In general machining and workshops, clamps are used daily for drilling, milling, inspection, and assembly.

From bench vices to step blocks and support elements, these tools help machinists maintain precision, safety, and productivity.

Across all industries, clamps serve one universal purpose – to provide control and stability. Whether in heavy manufacturing or fine-precision work, clamps are a key support component in most industrial activities.

Benefits of Using the Right Clamp

Choosing the correct clamp is one of the most critical decisions in any machining or manufacturing setup. The right clamp ensures that workpieces are held securely, machines run smoothly, and end products meet the required quality standards.

Here are the key benefits of using the right clamp for your operation –

Improved Accuracy and Precision

A suitable clamp keeps the workpiece stable during machining, cutting, welding, or assembly. This prevents unwanted movement or vibration, allowing machines to work with higher accuracy.

Enhanced Safety for Operators

Unstable workpieces are a common cause of accidents in machining environments. The right clamp ensures the material stays firmly in place, protecting operators from sudden movements, tool slippage, or flying debris. This reduces workplace risks and builds a safer, more reliable production environment.

Reduced Setup Time

Using the correct type of clamp simplifies the setup process. Quick-action clamps, such as toggle or wedge clamps, allow faster loading and unloading of workpieces, saving valuable production time.

Better Surface Finish and Product Quality

Vibration and displacement during machining can lead to uneven surfaces or tool marks. The right clamp eliminates these issues by maintaining firm and uniform pressure on the workpiece. As a result, the finished product has a smoother surface and meets tighter tolerances.

Extended Tool and Machine Life

Proper clamping reduces stress on cutting tools and machines by minimising vibration and movement. Thus, it means less wear and tear, fewer breakdowns, and lower maintenance costs.

In the long run, using the right clamp contributes to the longevity and reliability of both equipment and tools.

Increased Productivity

When the workpiece is stable and the setup is efficient, machining cycles run faster and with fewer interruptions. The result is higher output and better workflow continuity. Manufacturers can meet deadlines more easily while maintaining consistent quality.

The right clamp is a crucial part of the machining process and directly affects quality, safety, and efficiency. Investing in high-quality, application-oriented clamps ensures smoother operations, improved precision, and long-term cost savings for any industry.

How to Choose the Right Clamp?

Selecting the right clamp for your machining or assembly process is essential to ensure stability, precision, and efficiency.

With so many types of clamps available, each designed for a specific function, it’s vital to evaluate your needs carefully before making a choice.

Here are some key factors to consider when choosing the right clamp –

- Type of Operation

Determine the process you are performing – milling, welding, drilling, inspection, or assembly. For instance, milling clamps are ideal for machining operations, while toggle clamps are better suited for repetitive tasks.

- Workpiece Size and Shape

Choose a clamp that can securely hold the workpiece without causing damage. Adjustable or modular clamps are suitable for irregular shapes, while heavy-duty clamps are best for larger components.

- Required Clamping Force

Consider the amount of pressure needed to hold the material firmly. Too little force can cause slippage, while too much can deform the workpiece. Hydraulic or wedge clamps provide higher force for heavy-duty tasks.

- Space Constraints

In CNC machining, space is often limited. Opt for low-profile or compact clamps that offer strong holding power without obstructing the cutting tool.

- Frequency of Use

If the operation requires frequent clamping and unclamping, quick-release or toggle clamps save time and improve workflow efficiency.

- Material and Durability

Select clamps made from high-grade materials, such as steel or alloy, to ensure longevity and resistance to wear and tear.

- Compatibility with Setup

Ensure the clamp integrates well with your existing machine table, fixtures, or tooling setup for smooth operation.

By evaluating these factors, you can select the most effective clamp for your needs – one that delivers stability, precision, and long-term value in every operation.

The Power of the Right Clamp

Clamps may seem like small components, but their role in industrial machining and fabrication is immense. From holding delicate parts in precision setups to securing heavy-duty components in large-scale manufacturing, the right clamp ensures accuracy, safety, and productivity at every step.

By understanding the different types of clamps and their applications, industries can optimise their processes, reduce setup time, and achieve consistent results.

Choosing high-quality clamps designed for specific tasks enhances machining performance and also extends the life of tools and machines.

Jaypee Associates offers the best selection of clamps, essential workholding tools, and toolholders. We deliver the most precise and efficient CNC machining tools for varied industries –automotive, aerospace, and general engineering.

Investing in the proper clamps helps create safer work environments, better-quality products, and smoother operations for long-term success. Contact today to learn more!