What is a Hydraulic Clamping System? A Complete Guide

- Home

- /

- What is a Hydraulic Clamping System? A Complete Guide

What is a hydraulic clamping system? Are hydraulic clamping tools essential in workholding? How do you choose the ideal hydraulic clamps?

Whether your business involves manufacturing, welding, or fabrication, hydraulic clamping systems are crucial.

As the name suggests, a hydraulic clamping system uses hydraulic fluid to securely hold workpieces in place. The system works with multiple CNC machining assemblies and delivers consistent force, improving efficiency.

As an authorised dealer of CNC machining and workholding tools and toolholders, we have a thorough understanding of various types of hydraulic clamping devices.

In this comprehensive read, let us focus on what hydraulic workholding clamps are and their advantages during CNC machining.

What is a Hydraulic Clamping System?

A hydraulic clamping system is an efficient workholding device that holds, positions, and secures workpieces during machining processes. It uses hydraulic fluid to hold the workpieces together during machining securely.

They are a powerful addition to various industries – from manufacturing to aerospace, construction, and railways.

As the machining industry shifts toward high-speed machining and automated production, hydraulic clamping systems provide a reliable, stable foundation.

Most types of hydraulic clamping systems are known for their ability to generate high clamping forces with minimal effort. The consistent pressure keeps the fluid moving and controls the clamping and unclamping movement.

The system reduces operational overload and delivers consistency across repetitive clamping activities. The remote operational ability further reduces manual labour and adjustments.

In the machining industry, hydraulic clamps are ideal when –

- High-speed machining is involved

- Heavy or large workpieces must be held firmly

- Precision and repeatability are essential

- Frequent loading/unloading is required

- Automated production lines are used

What is a Hydraulic Clamping System made of? How does it work?

For an ideal functionality, a hydraulic clamping system has several essential components –

- A hydraulic power pack or pump

- Hydraulic cylinders

- Clamping elements (such as swing clamps, work supports, or hydraulic vices)

- Valves, hoses, and fittings

Once activated, the hydraulic fluid flows through the system, generating a force that locks the workpiece in place with a level of consistency that manual clamping cannot match.

Hydraulic clamping systems are widely used in industries such as:

- Automotive

- Aerospace

- Die & mould

- Construction equipment

- Railways

- Heavy engineering

- Fabrication

- Precision manufacturing

In simple terms, a hydraulic clamping system gives manufacturers the confidence to machine quickly, safely, and accurately.

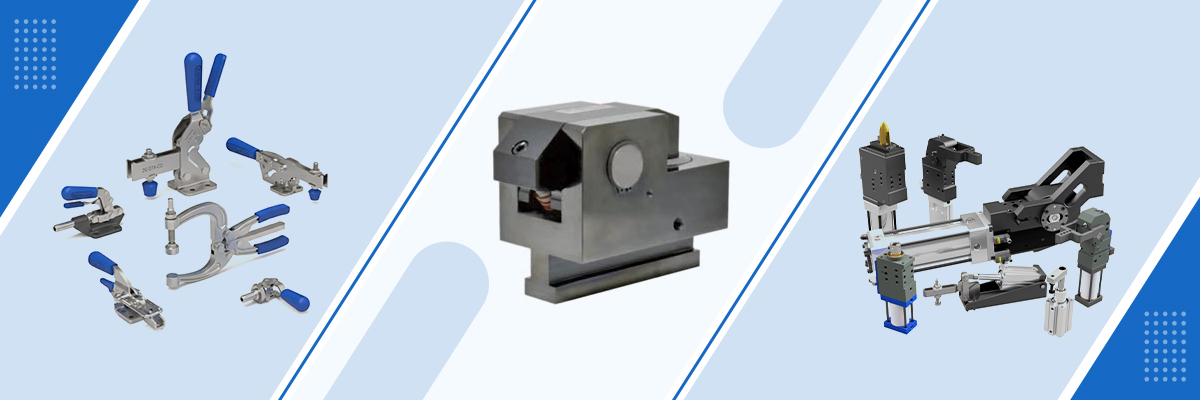

Types of Hydraulic Clamping Systems Used in Machining

Hydraulic clamping systems come in various designs, components, and usages. Each type is unique and designed based on its application, how it delivers force, the type of operation it supports, and the workpiece geometry.

Here are some of the most common and widely used types –

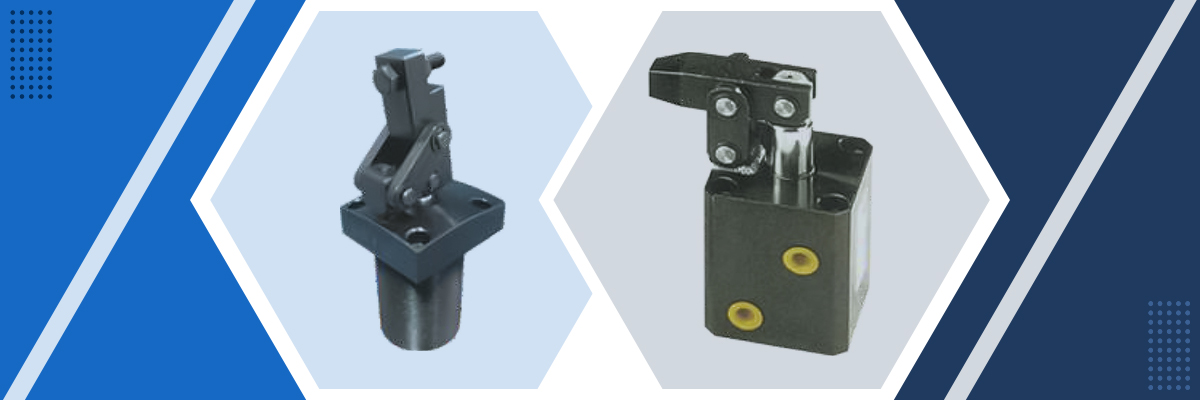

1. Hydraulic Swing Clamps

Swing clamps rotate (or swing) into position and then push down to clamp the workpiece. They are ideal for:

- Operations requiring top surface accessibility

- High-speed loading/unloading

- Fixtures with limited space

Hydraulic swing clamps are typically of two types –

- Single-acting swing clamps (use hydraulic pressure to clamp and springs to release)

- Double-acting swing clamps (use hydraulic pressure for both clamping and unclamping)

2. Hydraulic Work Supports

Work supports help stabilise weak or flexible workholding components during machining. They prevent deflection and vibration by lifting and locking the workpiece and serve as a reliable base.

Some of the common types of hydraulic work supports are –

- Spring-loaded work supports

- Fixed-height work supports

- Adjustable hydraulic work supports

3. Hydraulic Wedge Clamps

These industrial wedge clamping devices use tapered wedges to apply high downward or sideward clamping force. They effectively secure the workpieces in position while keeping the top portion free for machining. Hydraulic wedge clamps are ideal for –

- Heavy-duty machining

- Large and heavy workpieces

- High-force, low-movement clamping

4. Hydraulic Pull Clamps

Pull clamps use pressurised fluid and generate enough power to keep workpieces down onto the fixture for secure positioning and alignment. They are widely used in die & mould setups for automation benefits and compact design.

They work perfectly when –

- Holding milling machines and assembly lines.

- Positioning heavy beams and structures.

- Holding parts during welding or repair.

5. Hydraulic Vices

Hydraulic vices are powerful workholding devices that easily replace manual vices in high-precision machining. They offer consistent clamping force and allow for repetitive machining operations that demand stability, like –

- CNC milling

- Drilling

- Grinding

- High-volume production

6. Hydraulic Cylinder Clamps

These are straightforward hydraulic cylinders used as clamping actuators in custom fixtures. The mechanism is simple: hydraulic fluid pressure is converted to mechanical force and utilised for welding, machining, and assembly. They offer –

- Straight-line clamping

- High force

- Easy integration

7. Hydraulic Power Clamping Systems

These are fully integrated systems that operate multiple clamps simultaneously with the hydraulic pressure. The consistent, powerful support boosts productivity and safety and provides uniform clamping during various machining activities.

They are often used in –

- Automated production lines

- Robotic machining setups

- High-volume CNC environments

These are only a few of the standard hydraulic systems used across industries for machining needs. Each of these clamping systems is chosen based on application, workpiece size, fixture design, and machining requirements.

How a Hydraulic Clamping System Works?

The working principle of a hydraulic clamping system is straightforward: Force is generated when pressurized fluid acts on a confined area.

Therefore, each clamp provides a unique setup with workholding tools to direct the hydraulic fluid and support the machined parts.

Here’s the basic step-by-step working process –

- Hydraulic Pump Generates Pressure: A hydraulic power pack or pump generates hydraulic pressure by forcing oil through the system.

- Oil Travels through Hoses and Valves: Hydraulic hoses transport the pressurised fluid to the clamping elements. The valves regulate the direction, amount, and timing of this fluid flow.

- Hydraulic Clamps Activate: When hydraulic fluid reaches the clamp, it pushes against a piston inside the cylinder. This creates a force that –

– Moves the clamp arm

– Applies downward pressure

– Locks the workpiece in place

- Workpiece Is Held Firmly: Once clamped, the system maintains pressure so the workpiece stays firmly locked, even during –

– High-speed cutting

– Heavy metal removal

– Vibrating forces

– Multi-axis CNC machining

- Clamp Releases (Unclamping)

To unclamp, pressure is either reversed (in double-acting systems) or released (in single-acting systems).

The clamp arm retracts, allowing the operator or machine to remove the finished component.

In automated systems, clamping and unclamping can happen within seconds, allowing faster machining cycles and streamlined workflows.

Advantages of Hydraulic Clamping Systems in CNC Machining

Hydraulic clamping systems provide several advantages that significantly improve machining performance and production efficiency.

1. Consistent and High Clamping Force

Hydraulic systems deliver a stable, repeatable clamping force every time.

There is no human error or clamping variation, making them perfect for precision machining.

2. Faster Machining Cycles

Hydraulic clamps dramatically reduce setup time because –

– Clamping is quick

– Workpiece changes are faster

– Operators do not need to tighten clamps manually

This results in higher productivity and shorter cycle times.

3. Improved Machining Accuracy

Stable workholding reduces –

– Vibrations

– Deflection

– Inaccurate cuts

– Chatter marks

This leads to smoother finishes and tighter tolerances.

4. Enhanced Operator Safety

Since operators do not need to apply force manually, hydraulic clamps reduce the risk of –

– Slipping tools

– Pinched fingers

– Fatigue injuries

Safety improves greatly in high-speed machining environments.

5. Better Tool Life

Because the workpiece is firmly held without vibration, cutting tools –

– Last longer

– Stay sharper

– Break less frequently

This leads to reduced tooling costs.

6. Ideal for Automation and CNC Machines

Hydraulic clamping systems are compatible with –

– Multi-axis CNC machines

– Robotic loading

– High-volume production

– Auto-fixture setups

They support innovative manufacturing and welding practices across industries, from aerospace to railway and more.

7. Suitable for Heavy and Complex Parts

Hydraulic clamps can handle extremely heavy or irregularly shaped parts that manual clamps cannot hold securely.

Overall, hydraulic clamping systems boost productivity, precision, safety, and long-term cost savings.

How to Choose a Hydraulic Clamping Tool?

Selecting the right hydraulic clamping tool is vital for optimum performance, safety, and durability. When confused about how to pick the perfect hydraulic clamping tools, use the following criteria –

1. Type of Machining Operation

Assess the purpose of the operation; whether you are milling, drilling, grinding, turning, or inspecting. Each requires a different type of clamp.

2. Workpiece Size and Shape

What type of workholding tools and toolholders are being used matters. Large parts may require –

– Wedge clamps

– Power clamps

– Work supports

Small parts may need –

– Hydraulic vices

– Swing clamps

3. Required Clamping Force

Consider cutting load, speed, and the material’s hardness. Heavy-duty machining requires a higher force.

4. Fixture Design

Some clamps require more mounting space, while others are compact. Choose depending on the available room or workstation.

5. Automation Requirements

If used in robotic or automated setups, choose –

– Double-acting clamps

– Fast-response systems

– Integrated hydraulic manifolds

6. Budget and Scalability

Choose a solution that fits your budget but also supports future expansion. Specific hydraulic clamping systems, especially brands like Toolfast, are expensive. However, the common Toolfast clamping systems are affordable and reliable.

7. Safety Features

When it comes to safety during heavy machining, you will need –

– Pressure control valves

– Safety locks

– Leak-proof fittings

8. Industry Standards

For hydraulic clamping systems, opt for authorised distributors that comply with relevant policies. In aerospace or medical sectors, the clamp must meet strict quality and safety standards.

Maintenance Tips for Long-Lasting Hydraulic Clamps

Proper maintenance of CNC machining tools and toolholders extends life, ensures consistent performance, and reduces downtime. Here are essential tips:

Check for Leaks Regularly: Inspect hoses, valves, and fittings for oil leaks – even small leaks can reduce clamping force.

Keep the Hydraulic Oil Clean: Contaminated oil causes wear, corrosion, and poor clamping action. Replace or filter the oil as recommended by the manufacturer.

Inspect Clamping Pressure: Regularly verify that the system is generating the correct clamping force for the perfect machining setup.

Clean the Clamps and Fixture Surfaces: Dust the parts correctly, as metal chips can interfere with movement and sealing.

Lubricate Moving Parts: At the end of the day, even the best machining setup is a machine with movable parts. So, lubricate whenever essential, especially in swing clamps or pull clamps. Use manufacturer-approved lubrication.

Monitor Temperature: During machining, friction and heat are inevitable. Furthermore, excess heat affects oil viscosity. Ensure the system is not overheating during prolonged use.

Replace Worn Seals and O-Rings: Wear in seals can cause pressure loss or leakage, reducing productivity.

Schedule Professional Servicing: Periodic servicing ensures all components remain in optimal condition. Consult with distributors to understand and hire professional service providers.

Finding the Perfect Hydraulic Clamping System with Jaypee Associates

Hydraulic clamping systems have transformed modern machining by delivering unmatched stability, speed, and precision.

Whether you are machining heavy-duty steel blocks or producing small, intricate components, a hydraulic clamping solution ensures accuracy and efficiency throughout the process.

Their ability to provide consistent clamping force, reduce setup time, support automation, and enhance operator safety makes them an essential part of today’s manufacturing world.

Jaypee Associates has over 25 years of experience as an authorised seller of hydraulic clamping systems across industries. The experts onboard can help select the appropriate hydraulic clamp and provide maintenance guidance.

With us as supply partners, industries can significantly improve productivity while reducing long-term operational costs. With our advancements in CNC technology and the increasing demand for high-quality machining, our collection of hydraulic clamping systems will continue to play a vital role in shaping the future of manufacturing.

Explore our CNC machine toolings and workdholding fixtures!